|

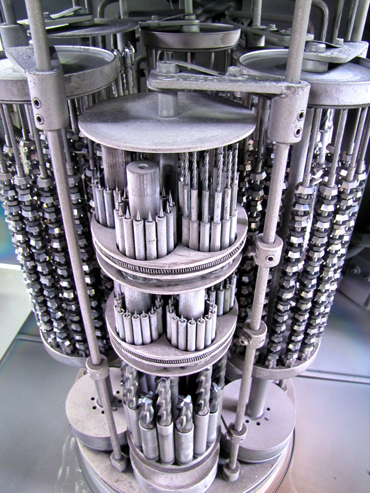

Towers of Tungsten ToolWorks, Ultra-Tool, Mil-Tec, and RoundTool Laboratories cutting tools cooling down after completion of a SmoothCoat® TA coating batch.

|

- PRICING IS SUBJECT TO CHANGE; CONFIRM PRIOR TO ORDERING

- 100% American Designed, American Owned, American Made! In every way, all the time.

- Expansion in Florida underway now; we are Doubling the size of our factory!

- Check out the SpeedsAndFeeds.com integration on most milling products!

- Smooth Consistency, Repeatability & Reliability... every single time.

- Need the very best indexable Milling products? Check our our sister company, Mil-Tec!

- Now PVD coating in both Florida and California to better serve you!

- Looking for a standard tool? Check out the huge selection at Ultra-Tool.com!

Tungsten ToolWorks is a manufacturer of customized (special) solid carbide cutting tools, sold worldwide under the Tungsten ToolWorks brand name. Products include solid carbide end mills, drills, reamers, burrs, micro tools, sub-miniature tools, micro tools, engraving tools, boring tools, keyseat cutters, burrs, slitting saws, carbide cylinders, countersinks, routers, radius mills, CBN tools, compression tools, and more. Technologies include SmoothCoat PVD hard coatings, SmoothGrind polished cutting edges, SmoothEdge prep and hone, and SmoothContricity shrink fit ready shanks. Coatings include D2 CVD diamond, D1 PVD amorphous diamond, TA TiAlN, AT AlTiN, TN TiN, TC TiCN, and A1 TiB2. Industries using our products include aerospace, semiconductor, die & mold, micro (nano) machining, woodworking, medical, consumer electronics, automotive and more. Workpiece materials to be drilled, milled, reamed, routed, engraved and more include titanium (6Al-4V, 5553), stainless (303, 304, 316, 410, 420, 440C, 15-5, 17-4, 13-8, 316L), tool steels (A2, D2, H13), general steels (1018, 1020, 4140, 4340, P20), Inconel (625, 718), cast iron, non-ferrous materials including aluminum, copper, brass, bronze, wood & plastics, CFRP (carbon fiber reinforced plastic), graphite, composites, fiberglass, and more. Tungsten ToolWorks is a Tool Alliance company.

Copyright © 2026 Tool Alliance. All rights reserved.